Quality is a permanent challenge that is realized day after day by all employees with the objective to lift the quality guarantee of our product continuously to a higher level. SIC purchases only the fully extensible “Clupak” sack Kraft paper quality & aluminum foil laminated paper, originated from Sweden, Austria, Bulgaria, Canada and other Scandinavian countries, to ensure the best quality products for its end users.

Our Company is committed to preserving the environment and believes in ensuring practices that conform to all international environmental standards. SIC conforms to all local environmental and quality standards set by the Environment Public Authority of State of Kuwait.

With its vast experience and commitment in providing the best products at the most competitive prices, has always kept pace with the technological developments and has thus been able to fully satisfy its wide customer base with top quality products.

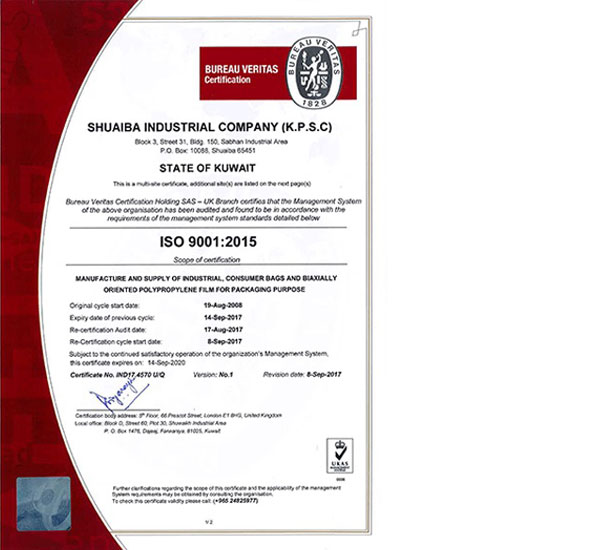

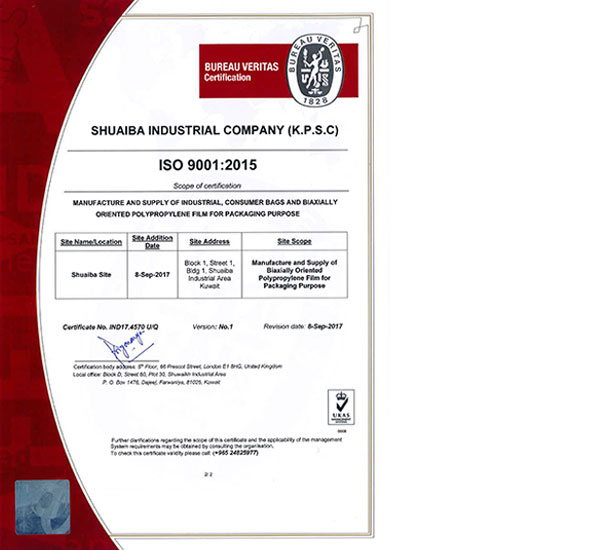

SIC obtained ISO 9001 certification in November 2001, thereby ensuring that all its products conform to International Quality Management System Standards. ISO 9001 is primarily concerned with quality management which means the organization fulfills the customer’s quality requirements and applicable regulatory requirements while aiming to enhance customer satisfaction and achieving continual improvement of its performance in pursuit of these objectives.

The Certification Council of Det Norske Veritas (DNV) has awarded the Hazard Analysis and Critical Control Points (HACCP) certificate for manufacturing and supplying paper packaging material for food industry to Shuaiba Industrial Co. K.S.C.. This makes Shuaiba Industrial Co. K.S.C. the Kuwait’s first paper converting company to obtain this certification. The HACCP certificate is the recognition of the product safety that has always driven to guarantee a safe food product to the consumer.

As already an ISO 9001 certified company, continuous product surveillance in all states of the production process is currently being integrated into the central operating system. Starting point is the proposition that products have to meet certain requirements before they are released to the next step. These steps are kept under close surveillance to guarantee the safety of the whole process. There is also a strong focus on the control of the supplied components. More specifically: paper, ink, and glue. SIC has set up the most sophisticated testing laboratory which assures the quality of every paper used.